A combustion engine drives the gas-powered “Lawn Mower“. It is not much different from powering motor vehicles.

know that learning just the best features of St.Augustine grass vs Centipede grass is not enough to maintain the lawn. However, understanding how you can fix low compression is also important to keep your lawn problem-free lawn. The term compression means the pressure in the piston chamber when a combination of air and fuel is squeezed. This ensuing explosion moves the piston outward and spins the crankshaft.

To fix low compression on lawn mowers, you need to determine whether damaged valves or piston rings have caused low compression. Take out the spark plug, and put a cap of W30 oil in the open cylinder. Then place compression tester on the spark plug hole.

Let’s delve into the details and learn more about fixing low compression on the mower.

Causes of Law Compression on Lawn Mower

Unfortunately, there is no single cause of compression problems. From piston complications, bad valves, to leak in the cylinder, there can be numerous reasons behind low compression.

Here we have briefly covered some possibilities that may cause low compression to help you understand the main source of the problem.

Holes in the Pistons

Located in the small cylinder of the engine, pistons receive a large amount of wear as they are next to the combustion. When you fire the mower’s engine, the pistons get blasted with a small explosion. When it occurs, the engine increases the compressed gases and causes movement in the piston.

This operates the main crankshaft. The overheating in the cylinder because of the extreme temperature creates holes in the pistons and lower compression.

Leaking Valves

Intake or exhaust valves in the engine face impairments because of an overheated cylinder. The high temperature can ruin or warp the valves which cause them not to close properly.

If the seal breaks down between the cylinder and the valves, the gases start leaking and the result is often compression loss.

Blown Head Gasket

Blown head gasket leak is the third culprit when it comes to low compression. The cylinder head is at the top of the block, and the gasket is located between the top and bottom of the engine of the car. The function of the gasket is to separate the oil from the air mixture and fuel while allowing all the gases to pass into the cylinder and cause combustion.

If the head of the gasket breaks between the engine block, it forms a hole and airspace in the cylinder. This failure can be the cause of overheating and low compression.

How to Fix Low Compression on Lawn Mower

Step 1: Check the spark plug

Find the ignition wire attached to the spark plug and distributor. Remove its end from the seat atop of the plug. You can do it by holding it firmly and pulling it at the base.

Try turning the plug with your hand. If the spark plug is not fixed, compression can leak via the hole it’s creating. You can use a ratchet set to fix or tighten the plug completely. Now, start the engine again.

Step 2: Check the bolts hold the top of the cylinder head

Inspect and examine the bolts holding the top of the cylinder head. These cylinder head bolts are typically set around the external edge of the cylinder head.

If the bolts loosen, they allow compression to escape from the cylinder. You need to use the ratchet set to constrict loose bolts and restart the engine.

Step 3: Inspect the valve lifters and pushrods

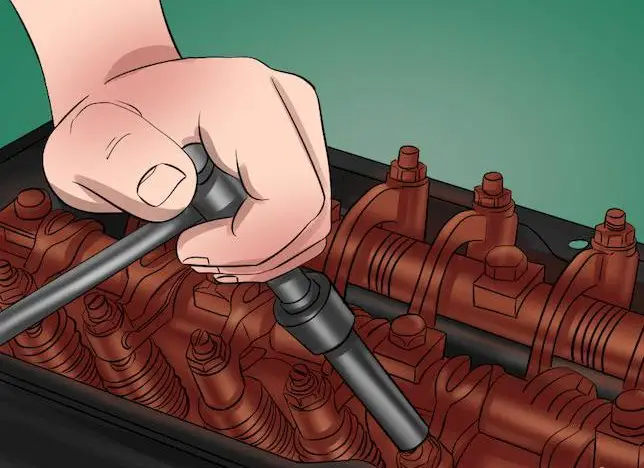

Remove the head cover of the cylinder and inspect the valve lifters and pushrods for damaged parts. If any part has dents or damages, it prevents a tight seal from making a lock within the cylinder.

The faulty seal reduces compression and if you find any broken parts, it is important to replace them.

Step 4: Test the compression

Determine if the worn valves or piston rings are causing low compression. Eliminate the spark plug, and fill the open cylinder with W30 motor oil. Now place the compression tester on the spark hole.

Disconnect or detach the ignition coil, and find the crankshaft of the engine.

Step 5:

Use a wrench to grab and turn the fixed crankshaft with a tester. It is better if you read the gauge, and evaluate the results to the usual compression range given by a lawn mower manufacturer. It will help you understand the mechanics and the right range of compression required by your lawn mower.

If the motor oil resolves the compression issue, the problem may be in the rings. If it doesn’t, the trouble may be a damaged valve. Check the valve for power loss, hard pull, and oil leaks. It may also affect the oil performance of your mower. Make sure you adjust it.

Summing Up

All in all, when the pistons of the engine are worn out or their seal is broken or bend, they lose compression. It can affect the performance of your lawn mower. If you want to keep your lawn mower moving, the best thing is to educate yourself about fixing its compression. Thus, the article includes the causes and steps to solve the problem of lawn mower.